Popular Posts Finding a one-stop shop for diesel engine filters The service needs of heavy-duty truck ADAS Truck powertrain downspeeding—how low can you go? Rand McNally expands its breakthrough vehicle telematics platform into new markets BYD unveils Type A school bus with V2G technology Connect with us advertise with us

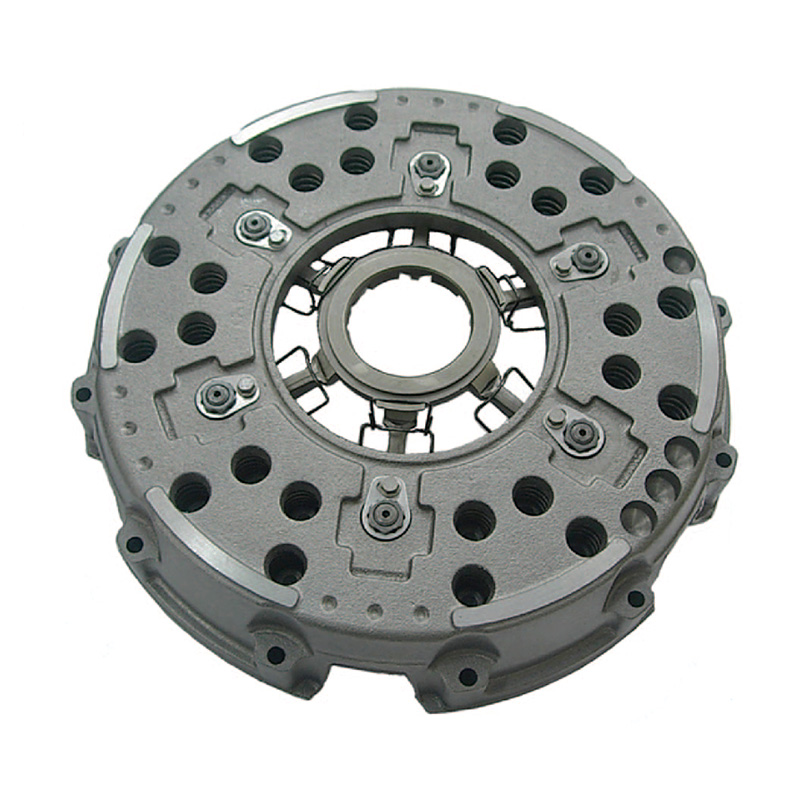

Finding a one-stop shop for diesel engine filters Clutch Assembly Replacement Cost

The service needs of heavy-duty truck ADAS

Truck powertrain downspeeding—how low can you go?

Rand McNally expands its breakthrough vehicle telematics platform into new markets

BYD unveils Type A school bus with V2G technology

Popular Posts Finding a one-stop shop for diesel engine filters The service needs of heavy-duty truck ADAS Truck powertrain downspeeding—how low can you go? Rand McNally expands its breakthrough vehicle telematics platform into new markets BYD unveils Type A school bus with V2G technology Connect with us advertise with us

Finding a one-stop shop for diesel engine filters

The service needs of heavy-duty truck ADAS

Truck powertrain downspeeding—how low can you go?

Rand McNally expands its breakthrough vehicle telematics platform into new markets

BYD unveils Type A school bus with V2G technology

Sponsored By High Bar Brands

File for the Employee Retention Credit Before It’s Too Late

Not sure if your business qualifies for the Employee Retention Credit (ERC)? If you made personnel adjustments due to issues with supply chain, capacity, project delays, or other COVID-related challenges, you could be eligible to receive up to $26,000 per qualifying employee through the ERC. Filing for this tax credit is only available for a limited time, so businesses need to act now to claim these funds.

Questions answered in this webinar:

Speakers Evan Alpaugh, Marketing Manager - Digital Acquisition, Stenson Tamaddon Alex Crissey, Editor, Transmission Digest

Fleet Equipment covers all the latest industry news and in-depth features related to trucks, tractors and trailers, including detailed information on the latest equipment components. Fleet Equipment tracks industry equipment trends, focusing on the issues that help fleets run the most efficient and productive trucks on the road. Fleet Equipment’s detailed editorial focused squarely on the equipment makes it an excellent resource for every fleet. The experienced editorial staff provides insights and solutions based on their many years in the trucking industry. Access to digital editions, contests, news, and more are ready for you today!

Fleet Equipment covers all the latest industry news and in-depth features related to trucks, tractors and trailers, including detailed information on the latest equipment components. Fleet Equipment tracks industry equipment trends, focusing on the issues that help fleets run the most efficient and productive trucks on the road. Fleet Equipment’s detailed editorial focused squarely on the equipment makes it an excellent resource for every fleet. The experienced editorial staff provides insights and solutions based on their many years in the trucking industry. Access to digital editions, contests, news, and more are ready for you today!

By Bower Heavy Duty Bearings by NTN on Oct 14, 2022

Urgency isn’t a new concept to the world of fleet operations and neither is flexibility. Being in an industry that changes everyday means it’s important...

According to some of the latest numbers from ACT Research, there are some positive and negative factors equally impacting the overall freight outlook. Let’s start...

There’s a shortage in just about every aspect of every industry. Driver shortages, supply shortages, technician shortages, parts shortages – they are all plaguing fleet...

If your trucks are operating in the long-haul segment carrying goods from New York to California, well, I hate to be the bearer of bad...

As a fleet manager, I’m sure you feel the pain as diesel prices reach new heights and while there isn’t much that can be done...

Automated driver assistance systems tend to get lumped together with monikers like “active lane keep assist” and “adaptive cruise control,” but the reality is that...

Christmas came early everyone! It’s our annual conversation with ACT Research President and Senior Analyst Kenny Vieth in which we unpack what happened in the...

Within the well-established ELD era, the next truck driver-focused technology mile marker seems to be planted firmly on the road to streamlining workflow beyond hours-of-service....

If we’ve said it once, we’ve said it a million times: There is no one size fits all solution or silver bullet to components used...

The correct set of tools and equipment will help your technicians perform to the best of their ability and provide them with the opportunity for...

The implementation of ADAS technologies has changed the game of fleet operations. With life-saving and collision-preventing features like emergency braking and active lane-keep, the automated...

Service: ECIA GIPC publishes China Tariff avoidance, recovery document

Heavy-duty: The biggest heavy-duty truck stories of 2022

Heavy-duty: Heavy Duty Aftermarket Week ’23 product expo nears capacity

EV Bizz: Optimal EV, Fontaine Modification repower conventional trucks and buses

Get the latest news, insights, and more delivered directly to you inbox.

We get it. Your wheel bearings are not at the top of your fleet inspection checklist, but just like your engine, transmission, or tires, ignoring proper maintenance procedures of your wheel bearings can cause damage.

The failure of your truck’s clutch bearings, for example, could sideline it and potentially cause further damage to the entire clutch pack assembly.

Two different bearings are incorporated into the transmission–the clutch pilot and the clutch release.

While engaged, the clutch pedal is at full height while the pressure plate forces the friction disc against the flywheel. The friction disc turns the Splined Input Shaft which drives the transmission to power road wheels.

While the clutch system is disengaged, the clutch release bearing is moved forward by the clutch fork. As the pressure plate compresses and the friction disc uncouples, the friction disc and input shaft are no longer being turned by the engine. The clutch pilot bearing rotates if there is difference between rotation.

To avoid a costly breakdown, here are some warning signs that indicate struggling clutch bearings that you may want to be on the lookout for.

– Grinding sounds as the vehicle is accelerating/decelerates after the clutch pedal is fully engaged;

– Steering wheel vibrations as the vehicle accelerates; or

– Bad smells as the clutch bearing begins to heat up.

– Whining/grinding during press/release of clutch pedal

– Clutch becoming stiffer as lubrication properties diminish

– Difficulty shifting gears in manual transmission

If you begin noticing the above observations, it may be time to replace your clutch bearings. Putting in the effort now to ensure your bearings are in working order and can meet application requirements will spare you unprecedented downtime later on.

The ever-increasing marketplace demand means it’s more important than ever to ensure your fleet is achieving optimal performance and dependability.

In order to achieve this, it’s important to double-down on equipment details. When it comes to bearings, the installation is simple, but the components are produced specifically to meet the tedious demands of operating conditions.

Before installation, it’s important to note the difference between high-temperature and standard clutch bearings and the applications they can be used for as they are not always interchangeable. To better understand which choice is best for your trucks and applications, check out the Bower’s video on the “Differences Between Standard Temp & High Temp Clutch Pilot Bearings” on the Bower Bearings YouTube channel.

Sponsored Content: Less weight, more strength: How composite spring suspensions apply both benefits

Sponsored Content: Protecting both sides of the trailer floor is the best way to combat corrosion and maximize service life and it’s one company’s mission to solve this industry problem

Sponsored Content: Case Study: New Cab Climate Solution Greatly Reduces Idling

Sponsored Content: 10 ways predictive maintenance with telematics data can boost fuel efficiency

Clutch Kit Parts Truck industry content for fleet owners and managers